But how exactly do these devices achieve those requirements?

In a recent Q&A, Endress+Hauser level & pressure product marketing manager Keith Riley provided an in-depth overview of how these instruments improve daily processes and how to get the most out of measurement devices across the industry spectrum.

How have 80 gigahertz radar level measurement devices evolved over the years?

KR: Over time, measurement functionality has increased from 6 gigahertz to 26 gigahertz and now 80 gigahertz. The 80 gigahertz sensors have improved functionality and accuracy. However, now we are seeing a real return on value for the customer based upon additional functionality that enhances simplicity, smart safety and productivity within a facility.

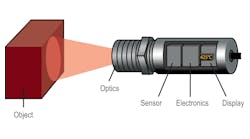

An 80 GHz sensor provides two basic advantages. First, increased signal strength measurement distances. Second, the possibility for simplified installation and commissioning. The narrower beam angle of an 80 GHz radar means the electromagnetic signal contacts fewer obstructions such as heating coils, agitator blades or even the side of the tank. Consequently, there will be less interference to filter.

How do 80 gigahertz devices impact safety?

KR: The added functionality from the HMI standpoint reduces human error by having commissioning wizards. This can help newer technicians easily and efficiently commission the device by reducing mistakes, reducing risk and enhancing safety. You have other functionalities, such as an SIL check wizard, which helps guard against human error when setting up a safety loop.

Most issues regarding safety loops are systematic failures, which are human errors in setting up the instrument or specifying the device. Those are more prevalent than actual random failures, which is what was originally focused on in safety instrumented systems.

How do these radar level measurement instruments enhance simplicity?

KR: The most basic way is the addition of a commissioning wizard. As smart instruments become more complex and companies deal with the attrition of their maintenance staff, "simple" commissioning can be challenging. This can be addressed with instrument-led commissioning procedures or wizards. Wizards will accurately and efficiently walk even an inexperienced technician through the commissioning process, eliminate menu hopping and identify when the task is successfully completed.

How and when does increased productivity come into play?

KR: The productivity will focus on things like Endress+Hauser's Heartbeat Technology, consisting of diagnostics, verification and monitoring functionalities, making smart instrumentation even smarter by providing reliable, in-depth sensor and process insights. It takes a lot of time to deal with the free space radar. You must get permits, climb to the top of the tank and more. Today, free space radar calibrations are generally performed in one of two ways: remove the instrument from the vessel and loop, take it to a maintenance shop to test it against a known distance then reinstall it; or locate a second access point to the tank, "dip" the tank and compare the values. Both require significant investments in time, increased risk to personnel and a loss of measurement.

Heartbeat verification checks all the critical functionality of your electronics. Suppose you can show that those are healthy and within specification with a high degree of certainty, in this case, greater than 95%. Then, you know that your measurement will also be accurate. This can all be done in situ without disrupting the measurement process and without the added risk to personnel that typically goes along with this.

Do free space radars benefit all industries?

KR: Absolutely. The 80 gigahertz device crosscuts across nearly all industries and in various types of applications. At Endress+Hauser, we make the 80 gigahertz radar for a wide range of liquid and solid applications in markets such as chemical, petrochemical, oil and gas, life sciences, food and beverage, water/wastewater and power and energy. So, again, they cut across all aspects of the marketplace, especially those where we operate.

How do plant operators know if an 80 gigahertz device suits them?

KR: It all comes down to working with experts and ensuring you have the optimum solution for your application. While applications might be similar, they are also unique based upon installation conditions and each customer's requirements. If you consult with an expert, such as Endress+Hauser, you will know if the instrument you are using is the right one, even if it is not an 80 gigahertz device. After an evaluation is completed, you can have peace of mind knowing whether your solution is the right one.